What’s the Purpose of a Feeder Pillar?

The Feeder Pillar is an external electrical enclosure and acts as a central hub for managing and controlling electrical distribution, housing and protecting components like circuit breakers, switches and fuses. They receive power from a main source and distribute it to multiple outgoing circuits including Streetlighting, traffic signals and EV charging points. Our cleverly designed in-built ventilation system ensures good air circulation and mitigates condensation.

The Everyday Workhorse - 3mm Mild-Steel

For trunk-road and motorway lighting, a 3mm strikes the balance between volume and durability. The shell is precision-lasered with welded construction and hot dip galvanised to BS EN ISO 1461 and has an excellent level of resistance to vandalism.

Designed to ingress protection IP54 with stainless steel hinges, fully accessible door aperture and a door seal gasket to IP65. Single door pillars have an integral root while double door pillars supplied with a bolt-on root.

5mm Mild Steel for Heavy Duty Applications

The heavy-duty 5mm shell carries the same galvanising and ingress-protection package as the 3mm range, but we swap the integral root for a bolt-on root so crews can unbolt a damaged shell without digging out the civils. With an 18mm backboard for larger switchgear, an excellent level of resistance to vandalism, plus a factory-fitted hasp-and-staple, the highway authority has the option of a padlock for higher-risk locations.

Stainless Steel – Strong, Tough and Corrosion Resistant

Galvanised steel performs admirably in most areas however in coastal and harsh environments, our stainless-steel range takes over due to its durability corrosion resistance even in the harshest environments. Fabricated in 304grade as standard, the cabinet leaves our factory painted Grey BS 18-B-25 but can be supplied painted to alternative BS or RAL colours or, brushed or mirror finish to suit the required aesthetics. The internal features are the same as our mild-steel pillars, i.e.: Stainless-Steel hinges, designed to ingress protection IP54, door seal gasket to IP65 etc so the only change for the installer is the material cost, not the fixing sequence or tools required.

Compact Traffic Solutions

Urban pavements rarely have space for a conventional size cabinet. Our 2200 traffic pillars are designed in a range of sizes from small single-door options to accommodate a street lighting cut-out and isolator through to larger double-door options for multi service isolation. Despite the slim profile, the shells are manufactured using 3mm galvanised steel with bolted construction, fully accessible door apertures, an integral root and door seal to IP65, ensuring the same quality as its larger cousins.

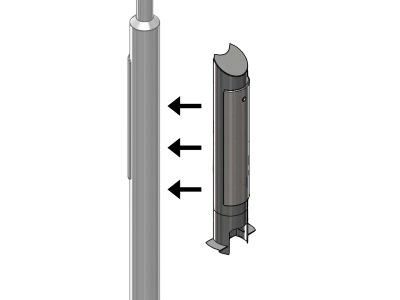

Wrap-Around Pillars

Some streets offer little or no pavement at all and columns often back straight onto railings, shopfronts or heritage stonework. For those scenarios the wrap-around pillar fits the bill perfectly. The ‘collar’ is designed to suit column diameters from 140mm to 219mm; the pillar is supplied in galvanised steel or can be specified in aluminium if preferred. Available root or flange mounted, these can be painted to any BS or RAL colour to blend with the existing column. Cables route through a short conduit into the column base, avoiding a fresh trench and keeping street furniture counts unchanged.

Heritage Styling Without Functional Compromise

Conservation officers often object to conventional galvanised feeder pillars. Our heritage feeder pillars answer the brief to provide a design which is in keeping with the surroundings. Available in a range of options with inlay panel/s and available in a wide range of BS or RAL colour options with single or two-tone inlay, these designs conceal the same 3mm or 5mm steel structures behind the façade. In-built ventilation is standard, and the stainless-steel hinges and IP rated door seals remain, so conservation officers get the required period aesthetics, and the electrical engineers get the required levels of quality and durability.

Pre-Wired Assemblies – On-Site Installation Time Reduced

Lane closures on motorways, dual carriageways or any major roads are extremely costly. By pre-wiring the distribution boards, surge devices, switches and fuses prior to despatch, the time taken to install these is substantially reduced and therefore reduces the cost of road or lane closures. We are committed to British manufacturing and the feedback from our customers is very positive.

Partner with Pudsey Diamond

Choosing the correct enclosure is paramount. Tell us the environment i.e.: motorway, coastal, industrial, or heritage sensitive, along with the required backboard dimensions, and we’ll match the material, finish, and pre-wiring (if required) to suit the application. Contact us and let the one part of your installation that nobody should notice keep doing its job, year after year, night after night, backed by the excellence of British design, engineering and in-house manufacturing.