Why Investing in Quality Electrical Distribution Pays Off

When budgets are under pressure, it can be tempting to choose electrical distribution equipment based on the lowest price. On the surface, cheaper feeder pillars and enclosures seem like a smart saving. In reality, they often lead to hidden costs - premature replacements, frequent repairs, and even safety risks - that far outweigh the initial savings.

At Pudsey Diamond, we’ve spent more than 40 years designing and manufacturing high-specification electrical distribution equipment. Our experience confirms one simple truth: quality isn’t a cost - it’s an investment. By choosing robust, carefully engineered enclosures, you gain reliability, reduce lifetime costs, and protect your infrastructure for decades.

Below, we explain why prioritising quality is the most cost-effective decision for your project.

Built to Last: The Durability Advantage

Low-cost enclosures are usually made from thinner, lower-grade materials. While they may meet basic standards, they’re far more vulnerable to:

- Corrosion and rust

- Accidental damage or vandalism

- Deterioration in harsh weather

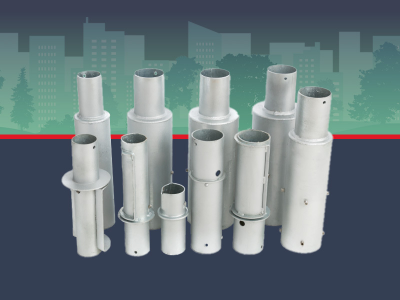

By contrast, Pudsey Diamond’s feeder pillars and heritage feeder pillars are manufactured from 3mm or 5mm galvanised steel or stainless steel. This superior construction ensures long-term resilience, reducing the need for early replacements. Investing upfront in durability means you avoid the mounting costs of failures and replacements - delivering real savings across the product’s lifespan.

Designed for Low Maintenance and Long-Term Savings

Maintenance costs are another hidden burden of low-grade equipment. Hinges that wear out, locks that fail, and poorly designed ventilation all increase the likelihood of costly callouts and downtime.

At Pudsey Diamond, we design reliability into every product:

- Stainless-steel hinges resist wear and maintain performance

- Anti-vandal locks protect against security risks

- Built-in ventilation helps safeguard internal components

These features minimise upkeep, reduce emergency repairs, and extend service life - making high-quality equipment the financially smarter choice over time.

The Value of Customisation and Smart Design

One of the most overlooked aspects of cost-effectiveness is the ease of installation. A generic, off-the-shelf product may not fit the unique requirements of your project. This can lead to costly on-site delays.

Pudsey Diamond's commitment to quality includes our in-house design and engineering processes. We offer pre-wired and custom-designed solutions that are tailored to the precise specifications of each project. This ensures a straight-forward installation process, saving significant time and cost. Our designs also focus on maximising internal space efficiency.

Choosing a pillar that is custom-built for your needs is a very intelligent approach, offering better value for money and ensuring that every component is working optimally for your specific application.

Smarter Installation with Customised Design

Generic, off-the-shelf enclosures rarely fit project requirements perfectly. Poor fit can lead to delays, redesigns, plus added delays and expense on site.

That’s why we offer:

- Custom-built solutions tailored to exact specifications

- Pre-wired options for faster installation

- Optimised internal layouts to maximise space efficiency

By ensuring a perfect fit from the start, our bespoke approach helps you save both time and money during installation - while guaranteeing long-term operational efficiency.

The Hidden Costs of Failure: More Than Just Repairs

Perhaps the greatest risk of low-quality distribution equipment is failure. An unreliable pillar can cause:

- Service outages and disruption

- Safety hazards for workers and the public

- Reputational damage

- Significant financial liability

Choosing Pudsey Diamond means choosing proven reliability. Our products are engineered to protect your infrastructure, support uninterrupted performance and safeguard your peace of mind.

A Smarter Investment for Long-Term Value

When viewed over 20 to 30 years, the price gap between a cheap enclosure and a premium-quality one is negligible. What makes the real difference are the avoided costs - less maintenance, fewer replacements, reduced risk and greater safety.

By investing in Pudsey Diamond equipment, you’re not simply buying a product - you’re securing the future performance and resilience of your infrastructure.

Are you ready to make the smart choice?

Get in touch with the Pudsey Diamond team today to discuss how our high-quality electrical distribution solutions can support your project.